Medical Device Testing

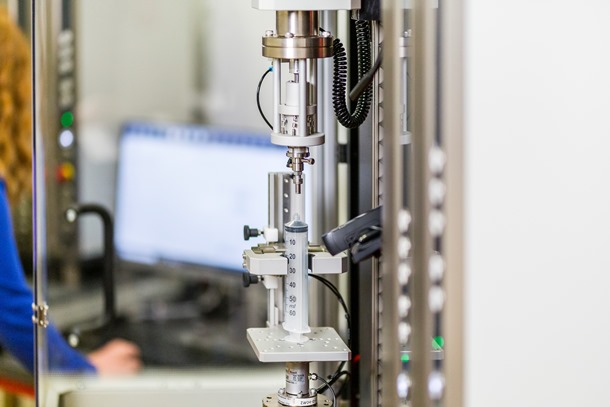

Since over twelve years our ‘Pharma Division’ is specialized in providing performance testing services to our customers from all over the world. We do not only test according to standards (ISO, EN, DIN, etc.). We also develop and validate customized, individual solutions adapted to the requirements of your medical devices and offer a wide range of fixtures for accredited and not accredited tests.

Our portfolio includes testing according to the current standard, test plan development, (design) validation and verification, aging and preconditioning for

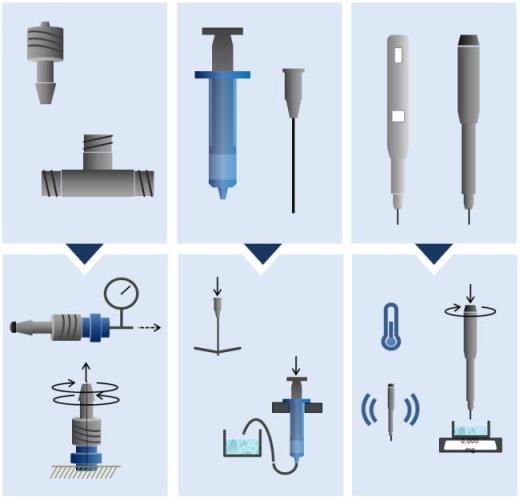

Drug Delivery Systems (Combination Devices)

Syringes and Needles (Combination Devices)

Anaesthetic and Respiratory Equipment

Others (Stents, Instruments, Auxiliary Devices)

Improved quality and safety through latest test methods and supportive technology

During the last few years we put much efforts in further increasing the quality and traceability of testing as well as on improving our time-efficiency. As accuracy and reliability are paramount to product safety, we use supportive technology such as Climate Chambers in various sizes for preconditioning and accelarated ageing, 3D - Printer for customized, individual solutions and reproducable test conditions or High Resolution Microscope for microscopic signs of failure and supportive interpretation of test results.

Improved Performance and Safety in everyday clinical use, taking into account Use Cases and Human Factors (Usability) Studies

The specifications of the standards regarding setup and performance of tests are very strict. Nevertheless, factors of various kinds can influence and affect the performance of the medical device. Such factors can be in the design of the device itself, but also in its interaction of the device with its user within an environment that simulates its real environment of use in all its variety (medical staff, patient). Based on our multidisciplinary background and our expert knowledge, we support you in identifying those factors that affect the safety and performance of your device in everyday clinical use and in deriving suitable testing procedures to cover these factors. In this way, application errors and their consequences can be minimized in the development process. In particular, the fulfillment of certain performance criteria of the medical device can be proven in the approval process without the need for time-consuming and cost-intensive clinical studies.

Accreditation

SpineServ GmbH & Co. KG is accredited according to DIN EN ISO/IEC 17025, which is an accreditation accepted by the FDA.

- DAkkS scope of accreditation (PDF-Download)

- DAkkS accreditation certificate (PDF-Download)

- a2la accreditation certificate and scope of accreditation (PDF-Download)